The Role of Warehousing in an Efficient Supply Chain

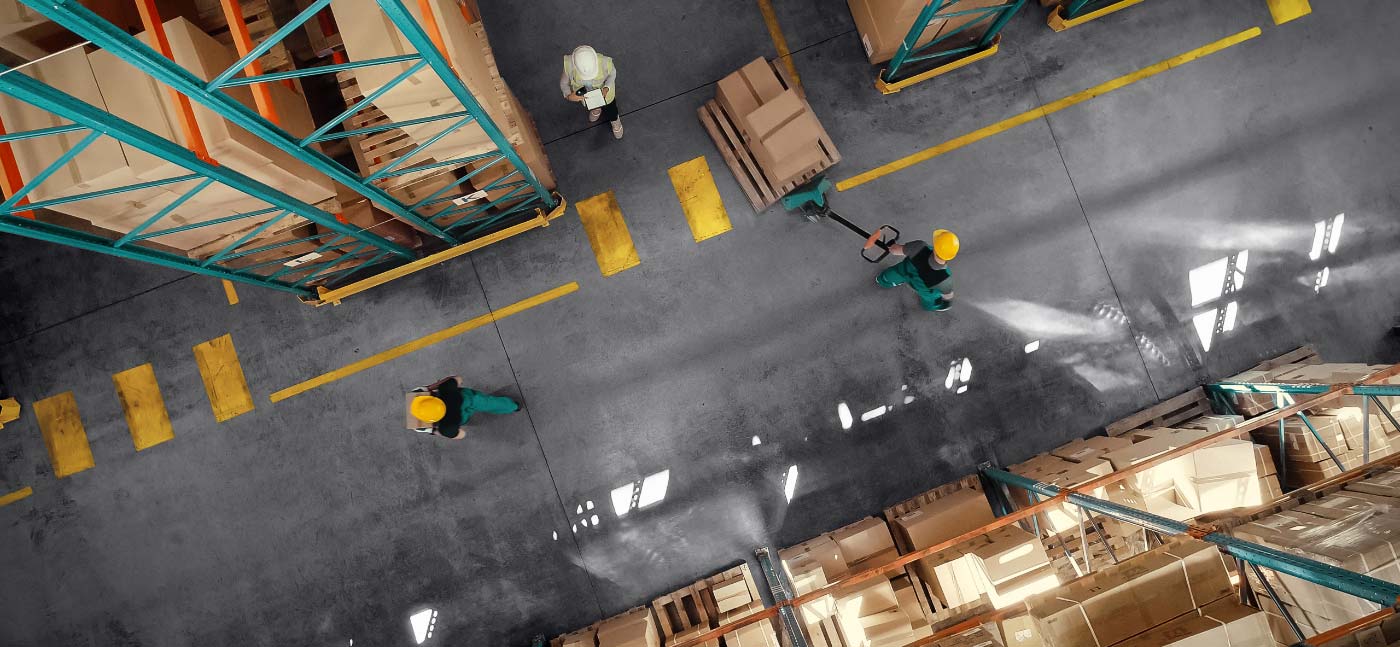

Warehousing plays a critical role in modern supply chains, serving as more than just storage facilities. Efficient warehousing ensures faster deliveries, optimized inventory management, and cost-effective distribution. Businesses that leverage strategic warehousing can enhance operational efficiency, reduce waste, and meet growing consumer demands.

In this article, we explore the key functions of warehousing and its impact on supply chain efficiency.

1. Inventory Management & Optimization 📦✅

Warehouses act as centralized hubs for storing goods before distribution, ensuring businesses maintain the right stock levels to meet demand. Effective inventory management reduces the risk of overstocking or stockouts, preventing unnecessary costs.

Key Benefits:

✅ Stock Control: Real-time tracking of inventory levels prevents shortages and excess stock.

✅ Faster Order Fulfillment: Organized storage layouts enable quicker picking and packing.

✅ Demand Forecasting: Data-driven inventory insights help businesses plan ahead.

Best Practices:

🔹 Implement automated inventory systems to monitor stock in real-time.

🔹 Use demand forecasting tools to predict inventory needs.

🔹 Optimize warehouse layout for efficient space utilization.

2. Faster and Cost-Effective Distribution 🚛💨

Strategic warehousing ensures quick and efficient order fulfillment, reducing lead times for both businesses and customers. By positioning warehouses closer to key markets, businesses can reduce transportation costs and improve delivery speeds.

Key Benefits:

✅ Reduced Transit Time: Shorter distances between warehouses and customers mean faster deliveries.

✅ Lower Shipping Costs: Storing goods closer to consumers cuts last-mile delivery expenses.

✅ Minimized Supply Chain Disruptions: Warehouses serve as buffers against transport delays.

Best Practices:

🔹 Multi-warehouse networks ensure goods are stored closer to demand centers.

🔹 Implement zone-based shipping strategies to optimize freight costs.

🔹 Utilize cross-docking to move products directly from inbound to outbound shipments.

3. Enhanced Supply Chain Resilience & Risk Management 🔄🔒

Warehouses act as shock absorbers in supply chains, providing backup inventory in case of demand fluctuations, transportation delays, or supply chain disruptions.

Key Benefits:

✅ Disaster Recovery: Buffer stock prevents disruptions due to weather, strikes, or port congestion.

✅ Reduced Supplier Dependency: Warehousing helps businesses manage supply fluctuations.

✅ Improved Order Accuracy: Quality control measures ensure accurate order fulfillment.

Best Practices:

🔹 Maintain safety stock to handle unexpected demand surges.

🔹 Diversify warehouse locations to reduce dependency on single hubs.

🔹 Use automated tracking to detect and prevent errors.

4. Value-Added Services (VAS) & Customization 🎯🏷️

Modern warehousing goes beyond storage; it includes value-added services (VAS) such as product assembly, labeling, packaging, and returns management. These services improve efficiency and streamline the supply chain by completing tasks closer to the point of sale.

Key Benefits:

✅ Faster Customization: Warehouses handle last-minute product modifications.

✅ Lower Labor Costs: Outsourcing kitting, labeling, and assembly reduces expenses.

✅ Efficient Returns Handling: Reverse logistics help manage product returns seamlessly.

Best Practices:

🔹 Offer on-demand packaging and labeling to customize products.

🔹 Utilize warehouse automation for faster assembly processes.

🔹 Develop efficient returns processing to enhance customer experience.

5. Technology-Driven Warehousing for Maximum Efficiency 🏭🤖

The integration of technology and automation in warehousing enhances speed, accuracy, and overall efficiency. Smart warehouses use AI, IoT, and robotics to streamline operations.

Key Benefits:

✅ Real-Time Inventory Visibility: IoT sensors track stock movement instantly.

✅ Automated Picking & Packing: Robotics reduce labor costs and improve order accuracy.

✅ Data-Driven Decision Making: AI-powered analytics optimize stock levels and demand forecasting.

Best Practices:

🔹 Implement Warehouse Management Systems (WMS) for real-time tracking.

🔹 Use robotic picking systems to increase speed and reduce errors.

🔹 Adopt cloud-based platforms for seamless coordination between suppliers and distributors.

Final Thoughts: Warehousing as a Competitive Advantage

An efficient warehousing system is a backbone of a high-performing supply chain. It ensures timely deliveries, cost-effective distribution, and improved inventory control—key factors in meeting customer expectations and staying competitive in the logistics industry.

🚛 Looking for reliable warehousing solutions? Horixon Global Transport & Logistics offers state-of-the-art facilities, advanced inventory management, and strategic distribution networks to optimize your supply chain. Contact us today!

Leave a Reply